Importance of Gas Regulators

Importance of Gas Regulators

Safety Considerations

In conclusion, pressure vessels are vital engineering components that play a crucial role in various industries. Their design, construction, and maintenance are governed by stringent standards to ensure safety and efficiency. As industrial processes evolve, the demand for high-performance pressure vessels continues to grow, making ongoing innovation in materials and design principles essential. With a focus on safety and efficiency, pressure vessels will remain indispensable in the industrial landscape for years to come.

The organization of natural gas is a complex tapestry of regulation, production, and distribution that is vital to meeting global energy needs. While the challenges are significant, the potential for natural gas to serve as a cleaner energy source presents immense opportunities. Through robust regulation, international cooperation, and innovation, the natural gas sector can contribute to a sustainable energy future, balancing economic growth with environmental integrity. It is essential that stakeholders commit to a unified and forward-thinking approach to navigating the future of natural gas.

Understanding Natural Gas Filters Importance and Functionality

Some PRVs are equipped with additional features, such as gauges and sensors, to provide real-time readings of pressure levels. Additionally, they can be adjusted manually or automatically, depending on the specific requirements of the system.

Despite its many benefits, the adoption of gasification technology faces some challenges. The initial capital investment for constructing gasifiers can be substantial, and the technology may require significant expertise to operate effectively. Additionally, the economic viability of gasification systems often hinges on the cost and availability of feedstocks, as well as market conditions for electricity, fuels, and byproducts.

Understanding Pneumatic Control Valves

Moreover, issues of global harmonization arise as businesses increasingly operate across borders. Different countries have varying regulatory standards, and this can create challenges for multinational corporations. Regulatory agencies are, therefore, beginning to collaborate more closely on international guidelines to ensure consistent standards that facilitate trade while protecting consumers. Such collaborative efforts are necessary to address challenges that transcend national borders, such as climate change and data privacy.

While there are various types of pressure regulating valves, they can generally be categorized into two main types direct-acting and pilot-operated valves.

There are several types of filters used in natural gas applications, each designed to target specific types of contaminants

Regular maintenance and testing of safety valves are essential to ensure they are functioning properly. Over time, valves can become worn or damaged, potentially compromising their effectiveness. By conducting routine inspections and tests, operators can identify any issues early on and take the necessary steps to repair or replace the valve as needed.

Applications of Relief Valves

The pharmaceutical industry relies on shut-off valves for precise control over the flow of liquids and gases used in drug production. Given the stringent regulatory standards in this field, these valves must ensure minimal contamination and maximum reliability. Similarly, in the manufacturing sector, shut-off valves play a pivotal role in processing applications where control over the flow of materials is essential to maintaining product quality.

Conclusion

While there are various types of pressure regulating valves, they can generally be categorized into two main types direct-acting and pilot-operated valves.

2. Two-Stage Regulators As the name suggests, these regulators use two stages to control pressure more precisely. The first stage reduces the pressure significantly, and the second stage fine-tunes it to the desired outlet pressure. This design is particularly beneficial for systems with varying inlet pressures.

In addition to electricity generation, gas plays a significant role in the heating sector, ensuring warmth in our homes during cold seasons. Natural gas heating systems are not only effective but also economically advantageous. Consumers benefit from lower energy bills compared to other heating methods. In many urban areas, the infrastructure for natural gas supply is well developed, making it a convenient choice for residential and commercial heating.

Gas pressure vessels, often referred to as gas cylinders or gas tanks, are essential components in various industries, providing a safe and efficient means to store and transport gases. These vessels are designed to handle high-pressure environments, ensuring that gases can be stored safely for commercial, industrial, and even medical purposes.

Electric regulating valves find applications in various sectors

3. Centrifugal Separators Utilizing centrifugal force, these filters separate particulates from gas streams. They are particularly effective in applications where high volumes of gas and particulate matter are present.

As we look to the future, the landscape of high-pressure organizations is expected to evolve. The Covid-19 pandemic has accelerated changes in work culture, leading many organizations to adopt more flexible and remote working arrangements. This shift presents opportunities for increased work-life balance but also poses new challenges in maintaining productivity in high-pressure settings.

Safety Considerations

Gasification Equipment Revolutionizing Waste to Energy Solutions

There are several types of relief valves, each suited to different applications and environments

In summary, pressure reduction stations are pivotal in the natural gas distribution network. They ensure the safe and efficient delivery of gas to consumers by managing high-pressure gas from pipelines, reducing it to suitable levels, and maintaining overall system integrity. With ongoing advancements in technology and infrastructure, PRS will continue to evolve, further enhancing safety and efficiency in gas distribution. Recognizing their importance not only underscores the complexity of gas distribution systems but also highlights the commitment to providing safe energy solutions to communities.

While pressure reduction stations are designed to be robust and reliable, they are not without their challenges. Regular maintenance is essential to ensure that all equipment functions correctly. This includes inspecting pressure regulators, safety valves, and control systems for signs of wear and tear or malfunction. Any failure in these components can lead to significant operational issues, including overpressure situations or insufficient gas delivery.

2. Digital Blood Pressure Monitors These are electronic devices that automatically inflate the cuff and display blood pressure readings on a digital screen. They are user-friendly and widely available for home use. Many models also store previous readings, which can be helpful for tracking trends over time.

As technology continues to evolve, precision voltage regulators are becoming more compact and efficient. The advancement of integrated circuits has led to the development of highly integrated voltage regulators that occupy minimal space while delivering high performance. Additionally, the emergence of digital precision voltage regulators, which can be programmed and monitored via digital interfaces, has enhanced flexibility and adaptability in various applications, allowing for easier integration into complex digital systems.

Understanding Skid-Mounted Equipment Efficiency in Modern Operations

Applications of Gas Pressure Regulators

Types of Electric Valves

Welded steel fencing is a popular choice for property owners looking to enhance security and add a touch of elegance to their outdoor spaces. This type of fencing is known for its durability, strength, and low maintenance requirements, making it a practical and attractive option for residential, commercial, and industrial applications.

This process requires precision to ensure the chain does not lose its strength This process requires precision to ensure the chain does not lose its strength

This process requires precision to ensure the chain does not lose its strength This process requires precision to ensure the chain does not lose its strength chain fence repair.

chain fence repair.

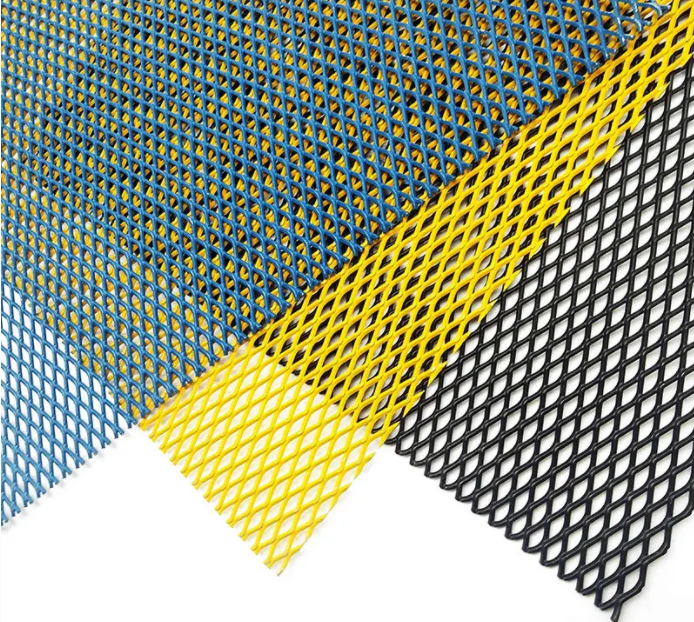

To ensure the longevity and effectiveness of the wire mesh fence, it's important to perform regular maintenance tasks such as inspecting for damage or wear, repairing any loose or damaged mesh panels, and treating the fence with rust-resistant coatings as needed. By staying proactive with maintenance, property owners can maximize the lifespan of their wire mesh fence and enjoy long-lasting security and peace of mind.

In summary, black annealed iron wire stands out as a robust and adaptable material suitable for numerous applications across different sectors. Its combination of strength, flexibility, and ease of manipulation makes it a popular choice among builders, farmers, and artisans alike. As industries continue to seek reliable materials that meet high standards of performance and durability, black annealed iron wire will likely remain an essential component in various projects. Its unique qualities make it not only functional but also valuable in enhancing the quality and efficiency of work in many fields.

In conclusion, the construction of a wire mesh fence offers a practical and cost-effective solution for property owners seeking security, durability, and versatility. By following these step-by-step instructions and investing in quality materials and craftsmanship, individuals can build a wire mesh fence that provides reliable protection and withstands the test of time.

Enterprising minds have risen to the challenge, developing techniques that allow for precise and controlled bending of welded wire mesh. One such method involves using specialized tools such as pliers, bending jigs, or custom-made fixtures to gradually manipulate the wire mesh into the desired shape.

The gauge of the wire should be chosen based on the specific needs of the property or livestock being secured The gauge of the wire should be chosen based on the specific needs of the property or livestock being secured

The gauge of the wire should be chosen based on the specific needs of the property or livestock being secured The gauge of the wire should be chosen based on the specific needs of the property or livestock being secured cost of barbed wire per meter.

cost of barbed wire per meter.Step 1: Gather the Materials